Plastic Moulding Process

Injection Moulding is a growing industry, and demand has been increasing for plastic injection moulders. However, despite its importance in the industry, the actual process behind plastic injection moulding is still a mystery to many people. This blog post is being written to try and explain the plastic moulding process, from the design to delivery.

The Process

1. The first step in the process is the creation of the mould.

This is a solid template that the plastic is injected into to create the plastic shape. They are manufactured to the proper specifications. They must also feature both the mould shape, and the cylinder in which the injection drill and plastic can go in.

2. The actual machine used for injection moulding can differ depending on the product.

Moldwel’s machines range from 35 tonnes to 328 tonnes. The products they can make range from 0.1 grams to 1050 grams.

3. The mould is clamped into the Clamping Unit of the machine.

This ensures the product is kept secure during the plastic injection and cooling. It must be set so that the injection unit, the large drill, can enter.

4. Plastic materials, usually in the form of pellets, are fed into the cylinder of the mould.

This is then melted down to a molten form. A motorised screw within the heating cylinder, forces the molten plastic to the end of the cylinder

5. Once the plastic has accumulated at the end, the injection process starts.

A carefully controlled screw or ram slowly feeds the plastic via drilling, or injecting, through the cylinder and into the mould.

6. After the plastic is injected into the mould, there is a “Dwelling” phase.

This is where pressure is applied to make sure every single cavity, within the mould, has been filled with plastic.

7. After pressure has been thoroughly applied, the plastic is allowed to cool within the mould and set form.

8. The clamping unit is opened up after the plastic has been allowed to cool.

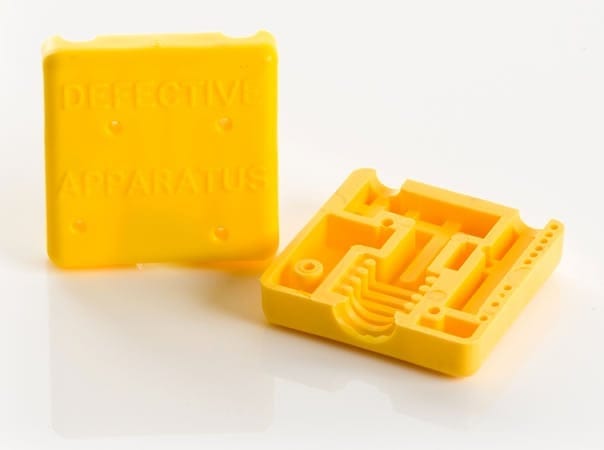

The two halves of the mould open and allow for easy removal of the plastic product.

9. An ejection rod, an ejection plate, or a blast of air will help push the plastic from the mould, resulting in a completed plastic product.

The plastics produced can range from individual pieces of larger items, to complete products themselves. For example; first aid boxes or electronic enclosures.

Contact Us

If you would like some more information on the plastic moulding process or our plastic injection moulding services, contact us today.

If you enjoyed this article, you might like to read our previous articles on “The Importance of Plastics in the Modern Day”