There has been a long line of success and indeed sustained growth within the plastics industry over the last 30 years or so. This is because injection moulded plastics are often the replacement for metal components.

At first there was a great reluctance to change; the majority of designers and engineers had only ever worked with metal and initially were unsure about changing. However, steel prices are ever-increasing and coupled with longer lead times, steel was proving less beneficial to manufacture with.

Plastic is more versatile, easier and cheaper to source, quicker to work with, and can produce more ROI than steel if used in appropriate applications. Injection moulded plastics are almost guaranteed to be the most cost-effective option.

What is Plastic Injection Moulding?

Plastic injection moulding is a manufacturing process that is used to create high volume batches of plastic parts. Plastic pellets – usually thermoplastic polymers – are melted into a liquid to begin with. They are then injected at a high pressure into a mould cavity. The mould is filled and the plastic then solidifies inside of it. The plastic can be popped out and the result will be a specific plastic part once cooled and hardened.

The moulds are made in the required part’s shape and size, and then can be used over and over to create accurate and consistent batches of the same product fact and efficiently. It is typically a mass-production process where the same part needs to be created hundreds, thousands, millions of times.

Related: Plastic Injection Moulding | From Design to Delivery

Injection Moulded Plastics

The main advantage of plastic injection moulding is the short time frame. Due to the mould being the same, you’re always guaranteed to get accurate results, incredibly fast. Once the mould has been made, there is very little labour required too. This means it is a fast and reliable manufacturing process – with little cost required in comparison to its production scale.

Plastic is one of the most versatile and reliable materials on the planet, which is why injection moulded plastics are continually on the rise. It’s available in thousands of different forms and is used worldwide for a wide range of applications. Whether it’s for furnishing, building, entertainment purposes, or communication, the list of plastic uses is ever-expanding.

Here at Moldwel, we’re proud to be one of the country’s leading plastic injection moulding companies. With so many different uses for plastic, there is also a lot of ways to manufacture with it. Plastic injection moulding is one of the most popular manufacturing processes.

Plastic vs Metal: The Advantages of Plastics

- The cost of ‘Raw Material’ in plastics is considerably less than metal – also production using plastic is far less labour intensive which gives clear savings in energy, wages costs and production time.

- Plastic weighs considerably less than metal ( despite retaining similar strength properties ) giving savings in component costs and also transport costs.

- It does not corrode or rust as metal does.

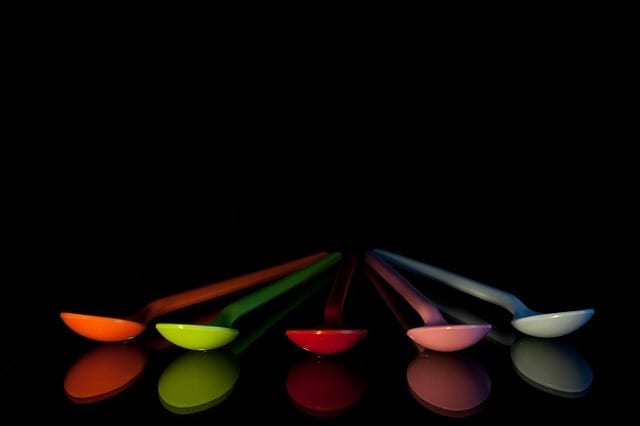

- Plastic components can be manufactured in any specific or matched colour – metal cannot – metal has to be painted or coated as a secondary operation, increasing production time and cost.

- The material can be manufactured easily in any design, shape or texture irrespective of complexity – metal cannot.

- Plastic injection moulding is far more efficient and cost effective, quicker and produces less scrap and wastage compared to metal.

- There are hundreds of different grades of plastics available all with different properties, strengths etc – metal is far more limited with its options.

Looking for plastic injection moulding companies?

If you would like to find out more about our injection moulded plastic services, then head to our website today. Alternatively, call 01922 631252 to speak to a member of our helpful and friendly team.

If you have found this blog helpful, you may wish to read a previous blog: Multi Use Plastics – It’s What We Do