Plastics replacing metals was first introduced in the 1950s through the invention of engineering-grade resins. But at the time, many manufacturers were unfamiliar with the advantages of this versatile production technique.

Save Costs By Switching From Metal To Plastics

Over the years there have been various advancements in cost-efficient plastics that are companies use to develop products. As a result, they are shifting the landscape of the market. Therefore, many industries are now realising the many benefits of replacing metal part manufacturing with plastic injection moulding. By making this change companies can expect 25-50% cost saving by just switching from metal to plastic.

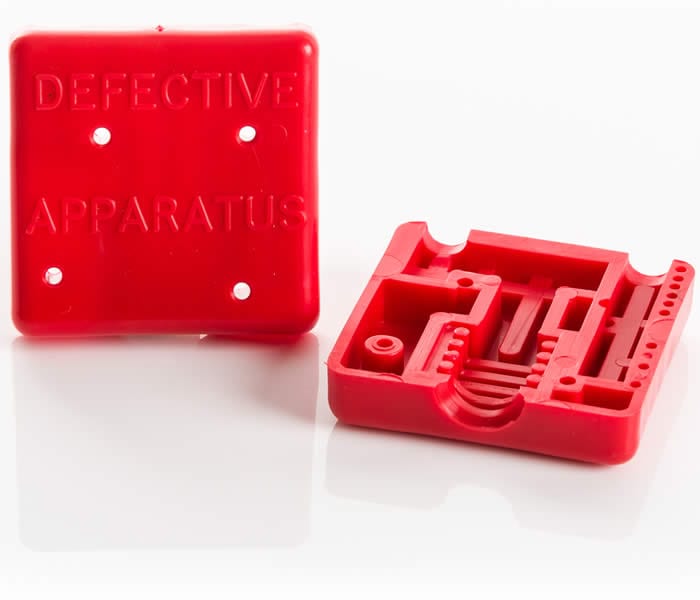

Plastic Injection Moulding

With so many industries turning to plastic injection moulding due to the increasing benefits, high-volume production and quick manufacturing process, plastic injection moulding is becoming the method of choice. So, let’s look at the advantages of plastics replacing metals:

- Plastic can have a higher tensile strength when compared to types of metals.

- Parts made from plastic are lighter and are able to reduce the overall product weight.

- Plastic has superior design flexibility.

- Helps to reduce manufacturing costs and waste.

- Plastic parts are created with a faster manufacturing method.

- Plastic parts can last up to six times longer.

- Plastics have increased corrosion resistance.

- Plastic material is perfect for repeatable, predictable manufacturing.

Fewer Secondary Operations

Changing from metal to plastic material allows for the consolidation of what would be several metal parts into one plastic part. As well as this, plastic products and parts require fewer secondary operations compared to metal parts, and this helps businesses to save on both time and manufacturing costs.

Making The Manufacturing Process Easier

Using plastics can help result in savings of 25-50% thanks to several factors. One of the main factors is that plastic injection moulding is able to replace multiple metal parts with one plastic part.

This means that parts of the manufacturing process can be diminished such as the fastener and assembly of the multiple parts. As well as this, plastic injection moulding also allows for various colours to be added. Consequently, helping to reduce the cost of the painting or laser marking section of the manufacturing process.

As well as saving on costs, plastic injection moulding can help to provide substantial improvements on the quality of the parts. This can be done through several ways including:

- Manufacturers are able to reuse plastic materials.

- There is an extended product life for plastic materials.

- Allows for more specialised and diverse design options.

- No need for a secondary process.

- Allows for the product to have greater structural strength.

- Lighter weight and improved ease of use.

For more information on plastic injection moulding and how it can benefit your business, contact us today.

If you enjoyed this article you might like to read our previous article, Key Terms to know…